A huge number of Solar panel chargers have been introduced throughout the nation starting around 2008 as additional Americans decide to involve sun-based energy in their regular routines.

While assessing sun-oriented modules for photovoltaic frameworks, it experiences its three fundamental module elective sorts. Slim film Solar panel charger, monocrystalline Solar panel charger, polycrystalline Solar panel charger.

These many sorts of Solar panel chargers utilize the sun to create power, however, each has remarkable qualities. Here, we will investigate polycrystalline sunlight-based cells. For more data on this kind of Solar panel charger, follow this new blog from Linquip.

Lately, individuals all over the planet have changed to manageable ways of life and become more energy productive.

Today, sun-oriented energy is utilized by a huge number of individuals because of its capacity to increase energy proficiency. One more component driving the establishment of sunlight-based chargers in homes is the increasing expense of power all over the planet.

These sun-powered chargers use PV (Photograph Valutic) innovation that bridles the sun’s energy and converts it into electrical energy.

The three fundamental classes of Solar panel chargers are right now available. These incorporate monocrystalline, polycrystalline, and flimsy film sun-oriented modules.

Be that as it may, polycrystalline sun-powered chargers are the most well-known of these three sorts of sun-powered chargers.

Here is the list of top 10 solar epc companies in India.

What is Polycrystalline Solar Panel?

A solar panel that contains numerous silicon crystals inside of a single PV cell is referred to as a polycrystalline or polycrystalline solar panel.

The wafer of polycrystalline solar panels is made of many pieces of silicon that have been fused. For polycrystalline solar cells, the cooling of the molten silicon required to create the cells is accomplished by the panel itself.

The surface of these solar panels resembles a mosaic. They are made up of several pieces of polycrystalline silicon, which gives them their square shape and dazzling blue hue.

In polycrystalline panels, there is extremely minimal electron mobility within the cell since each cell contains several silicon crystals. These solar panels harness solar energy and transform it into power.

The distinction is that the silicon crystals cool and naturally fracture as opposed to being extruded as a single pure ingot.

These fragments are melted in an oven, molded into cubes, and then thin wafers are cut from the cubes. This amalgam is made up of numerous distinct crystals, not the monocrystalline seen in solar cells.

Due to the more difficult production process compared to monocrystalline cells, more solar cells may be manufactured more quickly and economically.

There are no spaces between the bluish square polycrystalline cells since they are arranged closely together.

Due to the reduced space for electron movement caused by the molten silicon debris, polycrystalline solar panels are less effective than monocrystalline ones.

Polycrystalline modules typically have efficiencies between 13% and 16%.

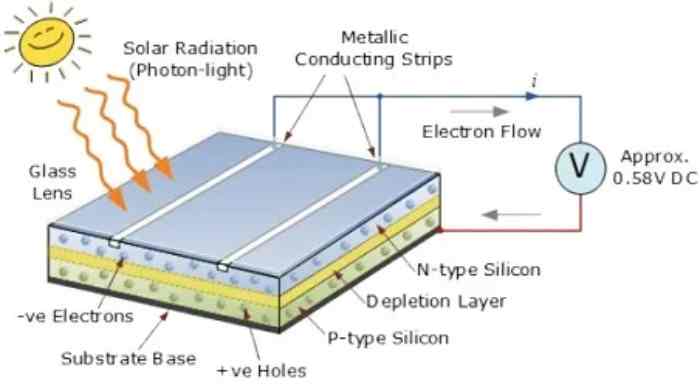

Working Principle of Polycrystalline Solar Panel

These Solar panel modules comprise numerous sun-powered cells. Every cell goes about as a semiconductor gadget and contains a silicon precious stone. Here you should also consider these different types of solar panel materials.

Photons from daylight invigorate electrons, and when they experience a PN intersection (an intersection of N-type material and P-type material), the electrons stream as current.

In this situation, the N-type material has a larger number of electrons than the P-type material. A PV cell is connected to two cathodes. The base terminal is a foil conveyor and the top cathode contains a little wire.

Features of Polycrystalline Solar Panel

- Contrasted with monocrystalline Solar panel modules, polycrystalline sun-based modules utilize less silicon during assembling and do not need a particular shape or game plan for every gem. Fundamentally less waste.

- The most extreme and least working temperatures of polycrystalline Solar panel chargers are 85°C and – 40°C individually.

- Contrasted with monocrystalline Solar panel modules, polycrystalline sun-based modules are less intensity safe. In this manner, these solar panel modules are less viable than ordinary Solar panel models at high temperatures.

- The power thickness of these boards is high.

- Cheap and simple to introduce as it is incorporated into the primary casing.

Also Read – Best Solar Power Manufacturers In India

Applications

- They are used in large solar parks to harness the power of the sun to power surrounding areas.

- They are used in stand-alone or self-sufficient devices such as remote traffic lights, and off-grid households. Here you can know more about the off grid solar system and how you can use it.

Advantages

- The price of the polycrystalline solar panel is cheaper than the monocrystalline panel.

- Polycrystalline slabs produce less waste due to the way the silicon wafers are attached to the slabs.

- They can be used in battery and Solar inverter technology.

- Very few fossil fuels are required in the manufacturing process.

Disadvantages

- Due to the lower purity of silicon, the efficiency of polycrystalline solar modules is lower than that of monocrystalline solar modules.

- They cannot stay that long.

- It is easily damaged when exposed to high temperatures.

You should also know about 5kw solar system in India. It is the perfect solar system for 2bhk and 3bhk houses.

Cost of Polycrystalline Solar Panel

The expense of polycrystalline Solar panel chargers is extremely low because of less waste and less energy in assembling. The least expensive Solar panel chargers are polycrystalline.

The size and limit of polycrystalline Solar panel chargers influence the expense. You need to pay as per your presentation. The table underneath shows surmised cost ranges for polycrystalline Solar panel chargers with various limits.

|

50 Watt Solar panel |

Rs. 1,500 |

|

100 Watt Solar panel |

Rs. 3,000 |

|

150 Watt Solar panel |

Rs. 4,500 |

| 200 Watt Solar panel |

Rs. 4,800 |

| 250 Watt Solar panel |

Rs. 6,000 |

| 300 Watt Solar panel |

Rs. 7,200 |

|

350 Watt Solar panel |

Rs. 8,000 |

It is an estimated Cost of a Solar panel. So, visit Solluz.co.in to get the accurate price list.

CONCLUSION

Assuming you have sufficient room to introduce Solar panel chargers, we suggest picking polycrystalline cells. Polycrystalline cells are marginally bigger than monocrystalline cells yet cost around 20% less to create a similar measure of energy.